Understanding Cummins Parts Cost: A Comprehensive Guide for Diesel Engines and Generators

In the realm of industrial machinery, diesel engines and generators are the backbone of countless operations, powering everything from construction equipment to critical infrastructure. Among the leading manufacturers, Cummins Inc. stands out as a global leader known for its reliability, innovation, and durability. When maintaining such high-performance equipment, understanding cummins parts cost becomes essential for businesses aiming to optimize operational expenses and ensure minimal downtime. This comprehensive article delves into the intricacies of cummins parts cost, exploring factors that influence pricing, strategies for cost-effective maintenance, and how engine-family.com can assist your business in managing these expenses effectively.

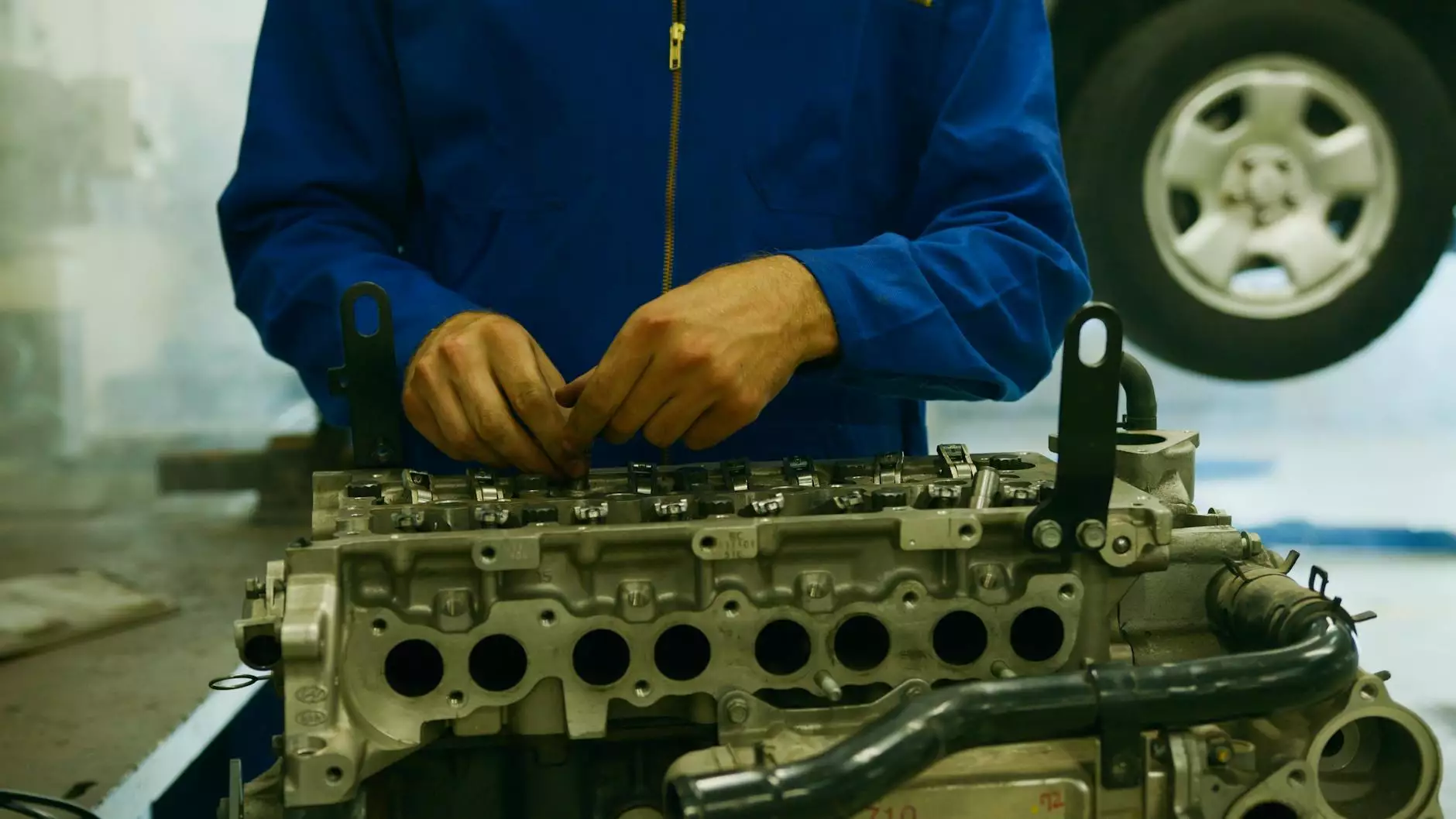

What Are Cummins Parts and Why Are They Critical?

Cummins parts encompass a broad range of components designed specifically for diesel engines and generators manufactured by Cummins. These include essential items such as injectors, turbochargers, filters, pistons, valves, and electronic control modules. The quality of replacement parts directly impacts engine performance, fuel efficiency, emissions, and overall lifespan.

Investing in genuine Cummins parts ensures compatibility, high quality, and adherence to manufacturer specifications, thereby maintaining the productivity and safety of your machinery. Conversely, opting for inferior or aftermarket parts may lead to increased cummins parts cost over time due to premature failures or suboptimal performance.

The Factors Influencing Cummins Parts Cost

Understanding what affects cummins parts cost is vital for implementing effective maintenance strategies. Several key factors influence pricing, including:

- Part Type and Complexity: More complex parts such as electronic control modules or turbochargers tend to be more expensive than basic components like filters or gaskets.

- Engine Model and Series: Different Cummins engine models have varying parts, with newer or specialized series often commanding higher prices.

- Original Equipment Manufacturer (OEM) vs. Aftermarket: Genuine OEM parts generally cost more but offer assured quality and compatibility. Aftermarket parts may provide cost savings but can vary in quality.

- Source of Purchase: Buying directly from authorized distributors or Cummins dealers ensures genuine parts but may involve higher costs. Purchasing in bulk or through authorized online portals might offer discounts.

- Market Conditions and Supply Chain: Fluctuations in manufacturing or supply chain disruptions can impact spare parts pricing globally.

- Part Age and Wear Status: Refurbished or remanufactured parts can be more affordable, though their lifespan and reliability might differ from new components.

The Breakdown of Typical Cummins Parts Cost

To help you better understand the financial aspects, here’s a detailed overview of typical costs associated with key cummins parts:

- Fuel Injectors: $250 - $600 each, depending on engine size and technology.

- Turbochargers: $1,200 - $4,500, influenced by engine model and design complexity.

- Filters (Oil, Fuel, Air): $20 - $150 per filter, crucial for preventive maintenance.

- Pistons and Cylinder Kits: $300 - $1,500 per set, essential for engine rebuilds.

- Electronic Control Modules (ECMs): $1,000 - $3,500, vital for modern engine management systems.

- Gaskets and Seals: $10 - $200, commonly replaced during major repairs.

- Starting Batteries: $200 - $600 each, important for reliable engine startup.

It’s important to note that these costs are approximate and can vary based on factors such as geographic location, supplier pricing, and engine specifications.

Strategies to Minimize Cummins Parts Cost Without Compromising Quality

While genuine Cummins parts are essential for optimal performance, managing cummins parts cost effectively is crucial for operational profitability. Consider the following strategies:

- Regular Preventive Maintenance: Routine inspections and timely replacements of filters, belts, and fluids prevent costly repairs and reduce the need for extensive part replacements.

- Bulk Purchasing and Partnerships: Establishing relationships with authorized dealers or bulk purchasing can unlock discounts and priority access to genuine parts.

- Utilization of Remanufactured Parts: Remanufactured components offer substantial savings and are often rebuilt to original standards, ensuring reliability.

- Investing in Skilled Technicians: Proper installation and maintenance prolong the lifespan of parts, reducing frequent replacements.

- Leveraging Authorized Distributors and Online Portals: Many certified suppliers offer competitive pricing and authentic parts, making maintenance more affordable.

The Role of OEM Parts in Cost Management and Reliability

Choosing OEM (Original Equipment Manufacturer) parts for your cummins parts cost strategy is often the best approach to ensure longevity, optimal performance, and compliance with warranty standards. Authentic parts are engineered precisely for specific engine models, providing several benefits:

- Guaranteed Compatibility: Eliminates compatibility issues that can arise with aftermarket components.

- Enhanced Durability and Performance: OEM parts are tested rigorously to meet stringent quality standards.

- Warranty Preservation: Using genuine parts is often a prerequisite for maintaining manufacturer warranties.

- Reduced Downtime: Higher reliability means less frequent repairs, ultimately saving money and time.

Although OEM parts may come at a higher initial cummins parts cost, their long-term benefits often justify the investment, especially for critical components.

How Engine-Family.com Supports Your Parts and Maintenance Needs

At engine-family.com, we specialize in providing high-quality Cummins parts tailored for a range of diesel engines and generators. Our platform offers:

- Comprehensive Catalogs: Extensive selections of genuine and remanufactured Cummins components for various models.

- Competitive Pricing: Access to affordable cummins parts cost through our exclusive partnerships and bulk discounts.

- Expert Support: Industry professionals available to guide you in choosing the right parts for your applications.

- Fast Delivery and Reliable Service: Ensuring minimal vehicle downtime and prompt maintenance.

- Warranty and Return Policies: Confidence that your investment is protected with quality assurance standards.

Our commitment is to help your organization streamline maintenance, optimize costs, and extend the lifespan of your diesel engines and generators.

Conclusion: Mastering Cummins Parts Cost for Business Success

Effectively managing cummins parts cost is more than just procurement — it’s an integral part of operational efficiency. By understanding the factors influencing pricing, emphasizing the importance of genuine parts, and adopting strategic maintenance practices, your business can maximize engine performance while minimizing expenses. Remember, investing in quality upfront results in significant savings over the long term, reducing downtime and increasing profitability.

Partnering with trusted providers like engine-family.com ensures access to authentic, high-quality Cummins components combined with expert guidance. Together, we can help your enterprise achieve sustainable growth, superior engine performance, and cost-conscious operations.